WHAT ARE POLYURETHANES?

To The Engineer they are materials offering a number of unique properties which enable products to be manufactured to meet a range of demanding applications.

To The Accountant they are materials which can be processed with low energy consumption and relatively low capital outlay for machinery to yield products which show cost savings through improved performance.

Polyurethane Elastomers are unique design and construction materials combining many of the advantages of rigid plastics, metals and ceramics with the extensibility of rubber.

It is not claimed that Polyurethanes are the answer to all problems but they are extremely versatile and this is the key to their widespread and growing use.

ELASTICITY

Elasticity refers to the property of recovering original shape after deforming forces are removed. Resilience is a measurement of the speed of this recovery as it occurs under special conditions.

Certain applications, such as die forming pads, require a rapid and complete recovery. Other applications, such as abrasion resistant linings, employ these same properties, but in a less spectacular manner. An elastomeric lining, being much softer than the commodity which it is handling, can only function efficiently if it possesses the ability to deform while absorbing the impact of individual particles in such a manner that it is not damaged by this deformation. The properties of elasticity and resilience are thus closely connected to abrasion resistance but are very difficult to measure or observe in the laboratory on the micro scale which represents actual surface abrasion.

CHEMICAL RESISTANCE

Chemical resistance is a very important performance property which can be built into polyurethane by several different means. Proper selection of the starting materials and manufacturing conditions are both necessary. Certainly, future coatings suppliers will offer polyurethane linings designed for specific chemicals instead of for general classifications.

Various chemicals possess different degrees of polarity and this fact provides the advance information that highly polar chemicals will permeate and swell linings which contain a large quantity of highly polar internal groups. The same reasoning applies to low polarity chemicals and low polarity linings. The correct approach to specifying linings is then to recommend a highly polar coating, for a low polarity commodity, such as gasoline.

Water is a very common chemical and one which causes great damage to many products, including polyurethane linings which are placed in service in non-recommended applications. The temperature of application greatly affects the reactivity of the water, which has the ability to chemically break down several chemical groups which commonly occur in polyurethane linings. This rupturing of the polymer chains is known as hydrolysis.

Additional factors also affect the success of both chemical and abrasion resistant materials. These factors especially include adhesion whenever a substrate is involved.

All polyurethanes are "breathable" materials. This means that vapour molecules, especially water vapour molecules, can pass through a polyurethane barrier by osmotic forces. This is especially important when other circumstances combine to cause high stresses on the adhesive.

Two such conditions which can be very important are:

1. Coating thickness - The relatively light gauge of a coating increases the opportunity for vapour molecules to permeate through and contact the substrate.

2. Temperature differentials - Whenever the substrate is significantly cooler than the temperature on the exposed surface, vapour molecules will pass through the coating and attempt to condense onto the cooler substrate.

Forces of condensation can become quite strong when temperature differentials are large. Water filled blisters will then occur whenever the permeation and condensation forces become stronger than the adhesive forces. Figure 8 illustrates these competing forces. Figure 9 is a schematic drawing of an apparatus which can create these adhesive stresses under laboratory test conditions.

ABRASION RESISTANCE

Abrasion resistance is a very complex property and undoubtedly requires acceptable levels of performance from a number of properties which may be measured individually. Certainly tear strength and coefficient of friction are important factors, in addition to elasticity. Heat resistance and low temperature flexibility are also important factors in certain circumstances. It is the interplay of these individual properties that is so difficult to. predict. Any one properly can be optimised but often at the expense of other properties

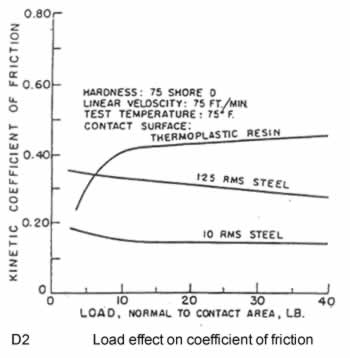

Figures D1 and D2 illustrate ways in which the coefficient of friction can-be reduced, ie., by reducing the load or by increasing the hardness of the elastomer. In fact, increasing the hardness will generally reduce the abrasion resistance because the elasticity is so adversely affected. Certain additives also reduce the coefficient of friction but may also adversely affect elasticity and tear. Coefficient of friction decreases very rapidly whenever the urethane substrate becomes wet or damp.

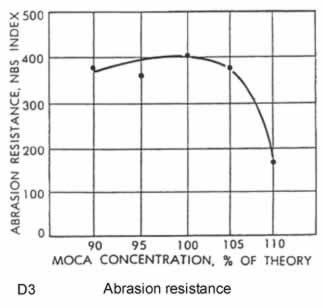

Figure D3 shows the measurement of abrasion resistance by the use of an NBS abrasion tester. This is one of a variety of laboratory abrasion tests, all of which correlate well with only a very limited number of field applications. This curve shown does, however, agree well with similar curves developed on other testers in that abrasion resistance does not change significantly between 90 to 105% of theory. The particular curative used, MOCA, is also typical of diamine curatives in that respect. A urethane formulation may thus utilise the percent of curative employed, within this particular range, to improve some additional property such as tear strength. An improvement in tear strength may provide a great improvement in abrasion resistance as measured on site. Laboratory abrasion tests are not usually severe enough to demonstrate the necessity of good tear strength when it is required.

RIGIDITY

Rigidity is a property which is utilised in certain engineering applications and is related to modulus values at low percentages. Very high rigidity is associated with compounds possessing low elasticity and is not within the scope of this discussion. Polyurethanes can, however, combine these two properties better, in many respects, than any other commercially available material.

Load bearing properties are also closely associated with both rigidity and modulus. Durometer tests constitute a measurement of load bearing performed on a micro scale. Compression modulus is the actual measurement of this property and refers to the weight per unit area required to compress a standard sample by a given percentage. Other than load bearing, durometer hardness values are primarily useful as quality control indicators and should be used with great caution for any other purpose.

TENSILE STRENGTH

Tensile strength is a topic of much interest to most people's concerned with the performance of polyurethane products. In fact, tensile strength is more of a curiosity than a crucial property. High values of tensile strength can appear impressive but actually are only incidentally related to performance features. Tensile strength is used in the laboratory as a quality control tool to verify the reproducibility of a specific quality level. Ultimate tensile strength is very seldom required in actual service applications.

FLEXIBILITY

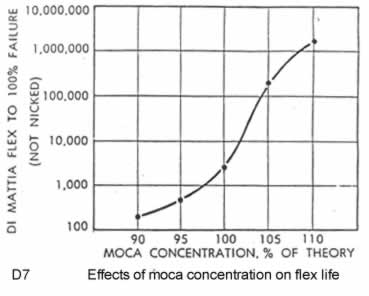

An additional performance property of much importance is flexibility. This property is measured in the laboratory on testing equipment such as DiMattia Flex Tester. Flex is a property which varies dramatically with the linearity of the polymer structure, as is shown on Figure D7. The increase in percent theory of the curative conesponds to increased linearity and thus greatly increasedresistance to flex cracking. Additives, such as plasticisers, can noticeably improve this property; however, this technique generally reduces other physical properties and should be closely tested for acceptability.

An apparently similar but basically unrelated property is that of low temperature flexibility. This refers to the fact that organic polymers stiffen at low temperatures and eventually become brittle.

Selection of the proper resin is the most effective means to obtain low temperature flexibility. Other factors may yet embrittle the resulting polymer, but without the proper resin, it is difficult to obtain this property. Polyurethanes will generally become brittle at temperatures ranging from 0°F to -100°F.

Generally, organic polymers will become more flexible at lower temperatures as longer carbon-to-carbon chains are incorporated into their basic structure. This is largely independent of whether the basic resin is a polyether or a polyester.

HEAT RESISTANCE

An accepted means of improving heat resistance is thus to increase the cross linking of a system so as to maintain a thermosetting character even though some degree of chain rupturing does occur.

Certain chemical groups can be developed within a polyurethane which will contribute to heat resistance (see Table IV). Also, a structure can be introduced which will resist the chemical rearrangements that occurs when a polymer chain is ruptured. This technique is effective but strongly affects other physical properties. 'A fact which should be definitely observed is the interdependency of the various performance properties upon each other._ A change which improves tear strength may adversely affect heat resistance, and vice versa. Performance properties, such as abrasion resistance, are thus quite difficult to test under laboratory conditions. There is no substitute for field service testing and good record keeping.

WEATHER RESISTANCE

Weather resistance is a very complex property which can be very dependent upon additives such as pigments, fillers, antioxidants, antiozonants and ultraviolet absorbers. The original resin, isocyanate and curative selections are also very important. There is no easily measured property which will predict weather resistance. Laboratory testing is therefore designed to simulate actual weathering conditions. A QUV Tester is" one such piece of equipment which combines varying temperatures, humidity's and exposure to ultraviolet rays.

One individual property which certainly contributes to the weather resistance of a material is heat resistance. Exterior ambient temperatures commonly reach 180°F on dark coloured surfaces and industrial applications for Elastomers often exceed this figure. The introduction of energy in the form of heat, into a polyurethane will often cause rupturing of the polymer chains. When this nrpturing has reached a certain stage, then a thermosetting polyurethane will revert to thermoplastic form and melting will occur.

ADHESION

Adhesion can be optimised by ensuring that the substrate is properly cleaned and prepared according to specifications. Metal surfaces especially should be primed immediately after cleaning or grit blasting in order to prevent surface oxidation. Recommended drying times and temperatures for primers and adhesives should be closely observed.

MODULUS

Modulus is a more meaningful measurement because it is closely related to the ability of a product to absorb energy, i.e., a low modulus urethane will deflect more easily to absorb the energy of a small particle than will a high modulus urethane. Again, property interactions become important and it will be observed that low modulus urethanes often possess poor tear strength. Sufficient tear strength must always be retained to prevent "chunking out" during exposure to the actual service conditions.

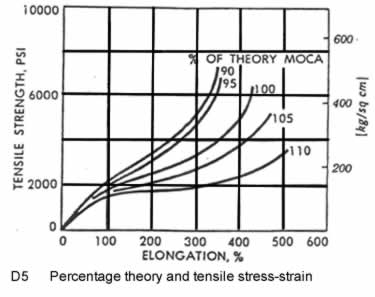

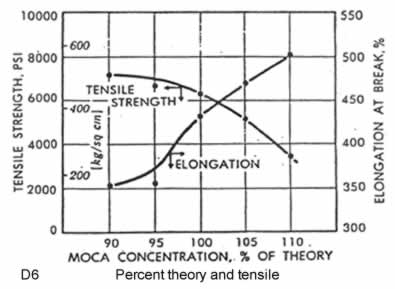

Figures D5 and D6 illustrate how changes in the percent theory of the curative affect both tensile strength and modulus.

TEAR STRENGTH

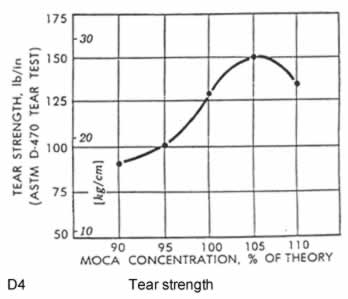

Figure D4 depicts the effect of curative percent theory on the development of tear strength. The physical significance of this curve is that 100% theory and greater, produces a very linear polymer. Whenever tearing stresses concentrate within the polymer, the molecular chains of a linear polymer can slide in such a manner as to relieve the stress but without breaking the chains themselves. Once sufficient slippage has occurred, a large number of chains will have accumulated in the stressed area, and may then provide sufficient resistance to withstand the applied stresses. This is accomplished somewhat in the same manner that a heavily starched and stiff cloth is much more easily tom than a loosely woven cloth of similar tensile strength.